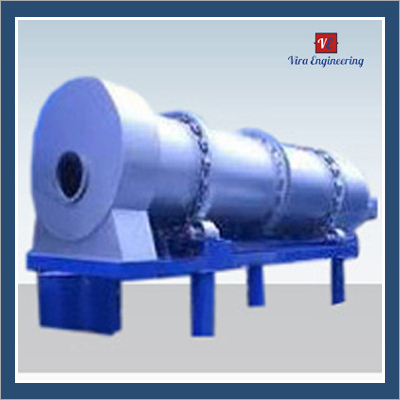

Fertilizer Drum Granulator

Product Details:

Fertilizer Drum Granulator Price And Quantity

- 200000.00 - 1000000.00 INR/Piece

- 1000000 INR/Piece

- 1 Unit

Fertilizer Drum Granulator Trade Information

- 20 Unit Per Month

- 7-20 Days

- All India

Product Description

Drum Granulator belongs to key fertilizer granulating equipment for making compound fertilizer granules. It can be applied to both cold and heat granulation with high medium and large scale production. It can make both low & high concentrations of compound fertilizer granules. The finish inside the drum is made by resistance rubber sheet. Moreover, Drum Granulator is known for its rust resistance, low energy consumption, easy operation and maintenance.

Rotary Granulator Belongs To One Of The Key Fertilizer Granulating Equipment For Making Compound Fertilizer Granules. Which Is Applyed To Both Cold And Heat Granulation With High, Medium And Large Scale Production.

The Granulating Method Is Rolling Round Particles In Wet Granulation. With Water Or Vapor Added Material In To Drum, The Material In Rotary Drum Are Blended Uniformly And Become Humid, During This Process, The Material Reacts And By Way Of The Liquid Environment And Rotation In Drum, The Material Particles Squeeze Each Other And Roll Into Particles. The Formed Particles Are Of 3-4Mm.

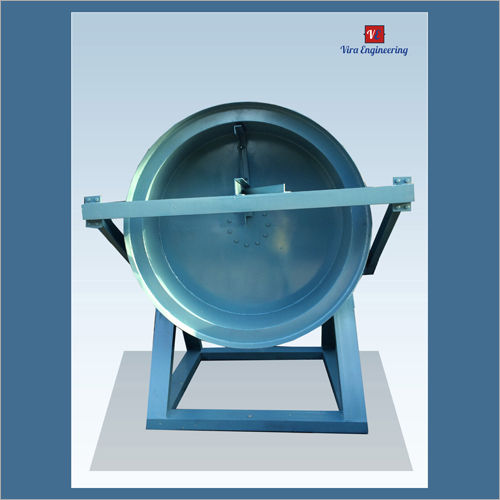

Advantages

- Large Granulating Capacity, Low Energy Consumption And Low Maintenance Cost.

- Flexible Fertilizer Particles Diameter According To Different Formulation, Processing Procedure And Raw Materials.

- Super Quality Steel Materials, Strict Quality Requirements And Control.

- Low Noise, Stable Performance Rational Structure Like Shoveling Plates To Clean Drums.

Product List

- Crushing Equipment

- Grinding Equipment

- Drying Equipment

- Screening Equipment

- Mixing Equipment

- Conveying Equipment

- Pelletizing Equipment

- Kiln

- Separation Equipment

- Feeding Equipment

- Pollution Controlling Equipment

- Storage Equipment

- Erection-Commissioning And R&D Services

Product details

| Country of Origin | Made in India |

| Capacity | 2 Ton Per Hour |

| Material | Stainless Steel |

| Brand | Vira Engineering |

| Driven Type | Geared Motor |

| Frequency | 60 Hz |

| Phase | 3 Phase |

| Rotary Speed | 6 RPM |

| Voltage | 440 V |

| Automation Grade | Semi-Automatic |