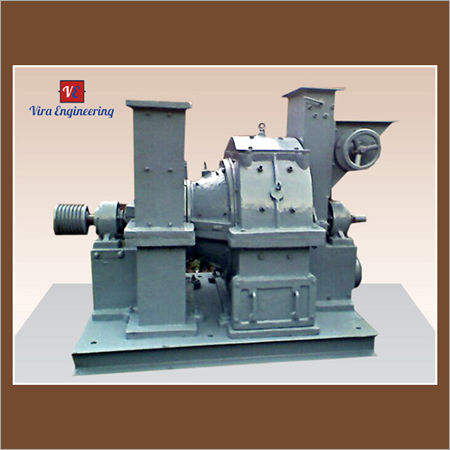

Grinding Pulverizer

Product Details:

Grinding Pulverizer Price And Quantity

- 1 Unit

- 200000.00 - 1000000.00 INR/Piece

- 200000.0 INR/Piece

Grinding Pulverizer Trade Information

- 20 Unit Per Month

- 7-20 Days

- All India

Product Description

The Pulverizer offered by us meets most capacity requirements. It changes to a wide degree of adjustment with the finesse of finished products. It is a grinding unit of heavy construction and build for continuous operation day by day. Moreover, it is specially designed for medium fine, and fine size reduction. The Pulverizer consists of various components like encased rotor carrying swing hammers, whizzer classifier for fineness regulation and pressure gradient creator mounted on a solid shaft.

The Impact Pulverizer Consists Of An Encased Rotor Carrying Swing Hammers, Whizzer Classifier For Fineness Regulation And Pressure Gradient Creator Mounted On A Solid Shaft. Raw Material To Be Pulverized Enters The Crushing Chamber Through The Hopper Or The Automatic Rotary Feeder. The Impact Of The Hammers On The Feed Material Against The Liner Plates Reduces It Into Fine Powder. The Ground Material Is Carried Towards The Whizzer Classifier For Classification And The Oversize Particles Are Rejected By The Classifier And Returned To The Crushing Chamber For Further Grinding. The Classified Material Is Then Conveyed Into The Cyclone For Collection And Bagging. A Dust Collector Is Provided In The System For Ensuring Dust Less Operation And For No Loss Of Ground Powder.

The Vira Engineering Impact Pulverizers Are Used For A Wide Range Of Application E.G. Agricultural, Chemicals, Carbon And Graphite, Coal, Coke, Coconut Shell And Wood Saw Dust, Clay, Dye Stuff And Pigments, Detergents, Ferro-Alloys Fertilizers, Fillers, Food Products, Herbs And Spices, Pesticides, Minerals, Plastics, Pharmaceuticals, Resins, Etc.

Advantages

- High Speed Rotor Assembly Two-Way Reversible Hammers / Beater

- Easy Access To Impact Pulverizers Interior Through Dual Access Doors

- Available In Different Size And Models

- Cold And Silent Running Dust Free Operations

- Robust Construction

- Low Specific Power Consumption

- Durable Long Life

- Guaranteed Grinding Efficiency, Particle Sizes Are Finer And More Uniform Than That Obtained From Machine Using Screen

Product details

| Frequency [Hz] | 60Hz |

| Machine Type | Pulverizer Machine |

| Material Grade | SS304 |

| Country of Origin | Made in India |

| Automation Grade | Semi-Automatic |

| Material | Stainless Steel |

| Brand | Vira Engineering |

| Color | Grey |

| Finishing | Color Coated |

| Driven Type | Electric |

| Corrosion Resistance | Yes |

| Voltage | 440V |

| Machine Capacity | 200kg/hr |

| Phase | Three Phase |