Magnetic Separator

Product Details:

Magnetic Separator Price And Quantity

- 1 Unit

- 200000.00 - 1000000.00 INR/Piece

- 250000.0 INR/Piece

Magnetic Separator Trade Information

- 20 Unit Per Month

- 7-20 Days

- All India

Product Description

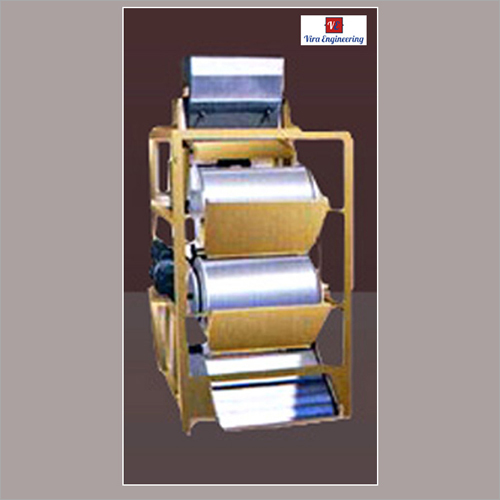

Magnetic Separator

In the Industries recent past the problem of removing the deleterious iron particles from a process stream had a few alternatives. Magnetic separation was typically limited and moderately effective. Magnetic separators that used permanent magnets could generate fields of low intensity only. These worked well in removing ferrous tramp but not fine paramagnetic particles. Thus high-intensity magnetic separators that were effective in collecting paramagnetic particles came into existence. These focus on the separation of very fine particles that are paramagnetic. By mechanism set the different type of magnets and pass the material from this layer and get the ferrous and non ferrous material.

There Are So Many Type Of Magnetic Separators According To The Requirements Of Users, We Can Offer Low, Medium And High Capacity Types Of Magnetic Separators. The Advantages Of This Magnetic Separator Are: Simple Structure, Large Capacity, Easy To Operate And Easy To Maintain There Are So Many Type And Structures As Per Application We Can Use It.

Advantages

- Single, Double, And Triple Drum Magnetic Separator

- High Power Magnetic Roll Separator

- Magnetic Drawer

- Magnetic Chute

- Plate Magnets (For The Conveyor)

- Magnetic Grill

- Inline Magnetic Separator

Product List

- Crushing Equipment

- Grinding Equipment

- Drying Equipment

- Screening Equipment

- Mixing Equipment

- Conveying Equipment

- Pelletizing Equipment

- Kiln

- Separation Equipment

- Feeding Equipment

- Pollution Controlling Equipment

- Storage Equipment

- Erection-Commissioning And R&D Services

Product details

| Material Grade | SS304 |

| Country of Origin | Made in India |

| Phase | Single Phase |

| Frequency | 50 Hp |

| Automation Grade | Automatic |

| Weight | Upto 600 kg |

| Voltage | 240 V |

| Power Source | Electricity |

| Brand | Vira Engineering |

| Material | Mild Steel |

| Usage/Application | Industrial |

| Capacity | 5tons/hr |