Rotary Dryer

Product Details:

Rotary Dryer Price And Quantity

- 1000000.00 INR/Piece

- 1 Unit

- 200000.00 - 1000000.00 INR/Piece

Rotary Dryer Trade Information

- 15 Unit Per Month

- 30 Days

- All India

Product Description

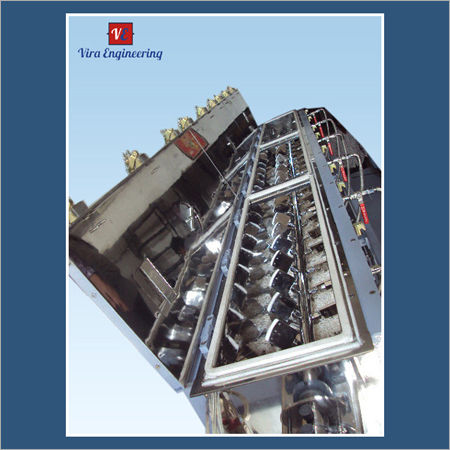

Rotary Dryer

Vira Engineering S Rotary Dryer Is A Type Of Industrial Dryer Employed To Reduce Or Minimize The Liquid Moisture Content Of The Material It Is Handling By Bringing It Into Direct Contact With A Heated Gas. Rotary Dryer Is Suitable To Dry Metallic And Nonmetallic Mineral, Clay In Cement Industrial, Chemicals, Foods, Fertilizer And Coal Mine, Etc.

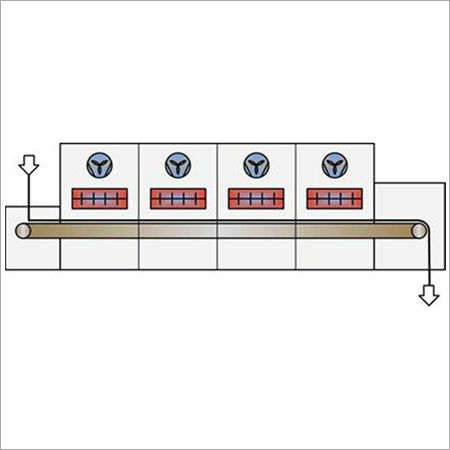

The Dryer Is Made Up Of A Rotating Cylindrical Tube, Usually Supported By Steel Structure. The Dryer Slopes Slightly So That The Discharge End Is Lower Than The Material Feed End In Order To Convey The Material Through The Dryer Under Gravity Or By Lifter/Screw. When The Wet Material Is In The Process Of Moving Forward In The Rotary Dryer Cylinder Body, The Lifting Plates Inside The Rotary Dryer Cylinder Makes The Material Up And Down To Contact With The Hot Flue Gas Completely. The Moisture Inside The Wet Material Is Evaporated Into Water Vapors, And Finally We Get The Dried Materials. This Gas Stream Is Move Co-Current Flow,

Vira Engineering S Giving The Heat Energy By Auto Combustion Burner. We Have All Auto Controller For The Firing System So We Can Operate It Easily And Safely Like Fuel Flow, Ignition, Temperature Controlling, Flame Air Controlling, Emergency And Auto On/Off Ext. We Can Use Any Type Of Fuel Or Gas For Direct Or Indirect Firing.

Advantages

- High Mechanization, Strong Production Capability And Continuous Operation,

- Simple Structure, Convenient Operation,

- Low Malfunction, Low Maintenance Cost.

- Wide Application Range And Good Drying Effect

Product details

|

Frequency |

50 Hz |

|

Power Source |

Electricity |

|

Usage |

Industrial |

|

Country of Origin |

Made in India |

|

Automation Grade |

Automatic |

|

Material Grade |

SS304 |

|

Heating Resource |

Biomass Pellets |

|

Voltage |

440V |

|

Material |

Stainless Steel |

|

Brand |

Vira Engineering |

|

Capacity |

5 ton/hr |